Decrease time to delivery, increase customer satisfaction

Companies in the manufacturing industry offer asset-maintenance services for their customers to ensure optimal performance of their installed devices and replace defunct parts as necessary. While the service allow manufacturers to stay engaged with their clients long after the initial sale of a component or device, the traditional approach of capturing and reporting on device condition using paper and pencil can impact the ability of field engineers to do their jobs efficiently. Generating asset reports manually leads to three substantial enterprise-wide headwinds: increased costs, slower time to delivery, and reduced revenue-generating opportunities.

Over the past 20 years, Steve worked as a Field Engineer for one of the largest manufacturers of liquid flow devices in the world. Steve’s work typically took the form of visiting a refinery or utility, locating and identifying his company’s devices, and then reporting on their condition. These tasks were all completed on paper and pencil, processed by data entry specialists back in the office, and then submitted to clients for reconciliation and approval.

Customer service was negatively impacted

by the time spent locating parts

Although Steve’s clients appreciated that they didn’t have to maintain an inventory of the assets themselves, the lack of an electronic inventory and report history vastly increased Steve’s time to delivery; Steve was often out of cell phone range at times he required clarification or support, and usually had to traverse across the facility to locate each device. Once Steve was finally able to identify the proper piece of equipment, he encountered a new set of obstacles when recording observations in uncontrolled environments on paper – rain, cold, wind, and a host of other conditions affected his work. These hand-written notes were consistently misread by the data entry specialists.

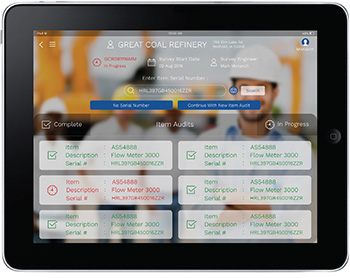

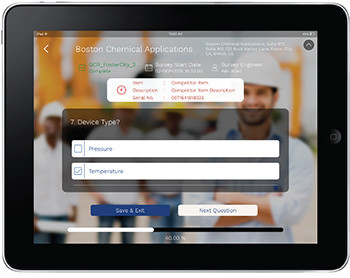

The company’s management decided that a mobile solution would help ease the workload of engineers like Steve and allow them to focus on higher value tasks – with the ultimate objective of improving customer service. They wanted a solution that was scalable, their engineers would love, and could integrate with their other corporate applications and systems of record: Monarch Field Audit checked all the boxes. Monarch Field Audit’s pre-built, industry designed user interface was easily customizable to their unique workflows and business processes.

Monarch Field Audit led to an exponential increase in revenue

Remember the manual tasks Steve had to complete on the front and back-end of a field inspection in the prior state? Now, after simply selecting a client name and facility on his mobile device, Steve has complete visibility to the quantity, type, and location of every device installed at a client facility. He is able to quickly complete an asset report with Monarch’s survey-based user interface, which he can then electronically submit to the office for reconciliation.

With universal access to a registry of his past visits to client sites, Steve is better prepared to arrive on-site with an immediate working knowledge of asset location and which may need to be replaced. Improved visibility to competitor’s devices at client sites arms Steve with more market intelligence, and an ability to up-sell and cross-sell his own devices.

Best of all, Steve’s clients are ecstatic with how much quicker Steve can execute and deliver reports.